Module assembly is much more than simply putting together individual parts. The units and systems are assembled painstakingly, using highly standardized processes that include a wide range of bespoke quality assurance steps. We use a combination of series and one-piece-flow assembly techniques to keep lead times down, cut your costs, and provide a more flexible range of options to help you be competitive in your market and respond to your customers’ needs. As assembly specialists, it doesn’t matter to us how big your individual components are, or whether you’re looking for small-batch or series production. From simple component assembly to the bonding and grouting of assembly parts and the assembly of complex products – we’re the perfect partner when it comes to producing your assemblies and assembling entire systems.

Our dedicated assembly team works on high-quality functional units across an area of over 4,500 m2. We stock individual components as necessary so that we can respond even more flexibly to our customers’ wishes.

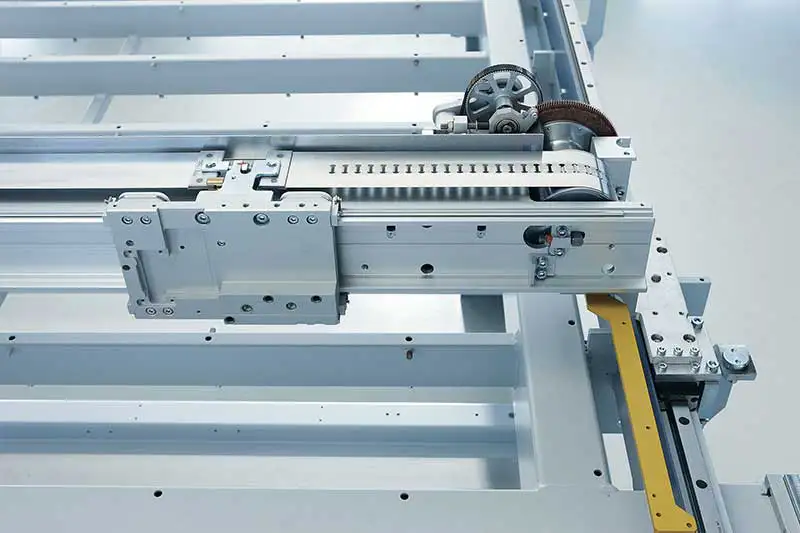

We have plenty of experience when it come to handling complex customer requirements, and always come up with innovative ideas and professional solutions to help you. Mechanical and mechatronic assemblies and systems have always had an important role to play in our holistic approach to problem solving. In order to make our end products even more efficient, we look at every detail, optimizing assembly steps and developing individual components further to produce the perfect solution.

The bases and equipment in our production facilities fulfill the strict requirements for ESD conformity. This enables us to prevent electrostatic discharge and assemble your module to professional standards. Our employees are provided with modern, lean workstations, and we consider ergonomic and optimized patterns of movement to be extremely important. Our experienced team carries out professional assembly, including the final inspection and functional tests, to ensure that every one of our products meets the highest standards in terms of quality.

All workpieces ordered from August Manser AG are shipped to our customers ready to install. Our high-tech cleaning plants use completely desalinated water, so they don’t leave any lime scale on your products.

Cleaning plant for:

Following testing, our components are packaged ready to use We employ the utmost care in both our manual and our automated packing processes, and label each component individually. This way, your assemblies and systems are always clearly marked and easy to find.

We also offer direct shipment to your end customers, delivering your products in line with your requirements and instructions. This saves you both time and costs, as we handle the entire logistics process.

Once assembly and function testing are complete, we document the features we’ve tested according to your specific requirements. On request, you can inspect the assemblies and systems yourself in our climate-controlled measurement room, where you can use high-precision coordinate measurement machines and optical testing equipment to validate the quality of your products.

Focused development and planning combined with a well-thought-out procurement concept and assembly lines customized for specific products – these are the essential components that allow us to optimize our resources and costs effectively.

The precise, zero-play, quiet, zero-friction steel belt drive by August Manser AG: